Why Choose Welded Wire Mesh for Your Project?

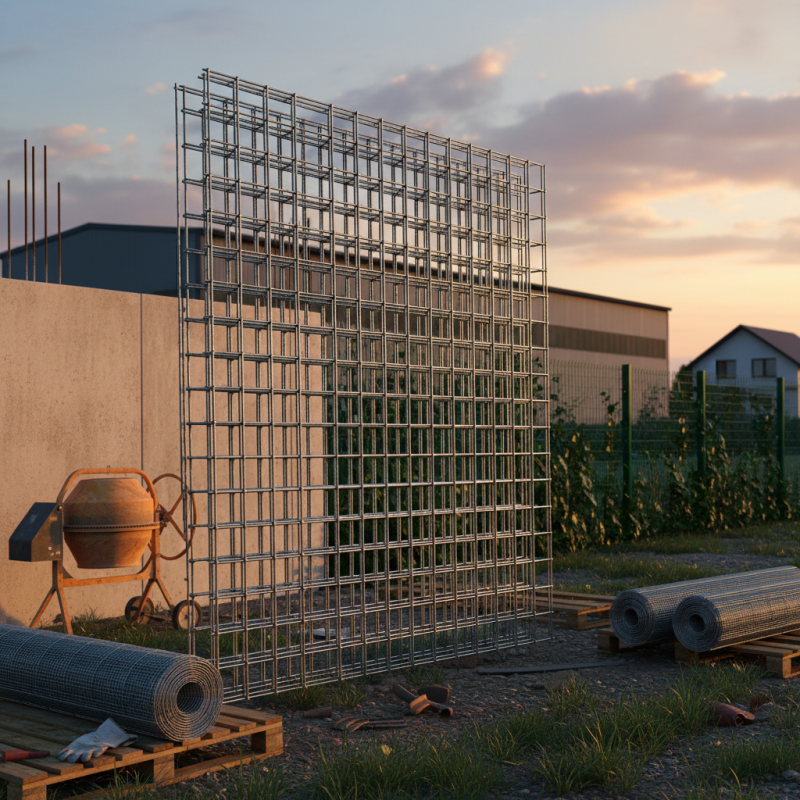

welded wire mesh is a versatile solution for various projects. It consists of wires that are fused together at intersection points. This construction provides strength and durability, making it ideal for many applications. The practical benefits are evident in residential, industrial, and agricultural settings.

When contemplating materials for your project, welded wire mesh stands out. It offers a cost-effective choice that doesn’t compromise on quality. The mesh is resistant to corrosion, ensuring longevity even in harsh environments. However, it requires proper installation to maximize its potential. Misalignment during installation can weaken the structure.

Choosing welded wire mesh can enhance safety and security. It can be used for fencing, reinforcement in concrete, or as a support for plants. Its flexibility allows for creativity on the job site. Still, one must consider the specific needs of the project. Sometimes, it may not be the perfect fit. Weighing options based on project demands is crucial.

Benefits of Welded Wire Mesh in Construction Projects

Welded wire mesh is a preferred choice in construction projects for several reasons. Its robust structure provides significant tensile strength. According to industry reports, welded wire mesh increases load-bearing capacity by up to 50%. This makes it ideal for foundations, walls, and reinforcement in concrete applications. The uniform spacing between wires ensures even distribution of loads, minimizing the risk of structural failures.

Another critical benefit is its ease of installation. Welded wire mesh rolls come in various sizes, allowing builders to customize according to specific project needs. The reduction in labor time can lead to cost savings of approximately 20% on average. However, some contractors overlook the importance of proper placement, which can undermine the mesh’s effectiveness. Proper training is vital to maximize its benefits.

Additionally, welded wire mesh contributes to sustainability. It is often made from recycled materials, reducing environmental impact. A study revealed that using welded wire mesh can decrease environmental footprint by nearly 30%. Yet, there's a challenge in sourcing quality materials. Not all suppliers meet industry standards, risking project integrity. Careful selection is essential to ensure safety and longevity.

Why Choose Welded Wire Mesh for Your Project? - Benefits of Welded Wire Mesh in Construction Projects

| Benefit | Description | Applications |

|---|---|---|

| Strength and Durability | Welded wire mesh offers high tensile strength, making it suitable for various structural applications. | Foundation support, flooring systems |

| Cost-Effective | Reducing labor costs and material waste makes welded wire mesh an economical choice. | Infrastructure projects, commercial buildings |

| Versatility | Available in various shapes and sizes, it can be used for a wide array of projects. | Walls, fencing, concrete reinforcement |

| Ease of Installation | Pre-manufactured panels save time during installation, reducing project timelines. | Residential and commercial constructions |

| Enhanced Safety | Strong structures reduce the risk of failure under pressure or impact. | Bridges, tunnels, high-rise buildings |

Versatility of Welded Wire Mesh Applications

Welded wire mesh is a versatile material widely used in various applications. Its strength and durability make it suitable for numerous projects. From construction to agriculture, its adaptable nature is impressive. According to industry reports, the global welded wire mesh market is projected to grow at a CAGR of 5.5% from 2021 to 2026. This growth highlights its increasing importance across sectors.

In construction, welded wire mesh is often used for reinforcing concrete. This application provides stability and improves structural integrity. A report by the International Journal of Science and Research states that using welded wire mesh can reduce the risk of cracking in concrete structures. In agriculture, it functions as fencing, keeping livestock safe. Its robust design withstands harsh weather conditions and animal impacts. Yet, the installation process can be tedious and time-consuming, requiring careful planning.

Welded wire mesh also finds use in industrial settings. It serves as safe barriers and is often used for security applications. Many warehouses use it for inventory control as it allows for visibility while ensuring safety. Despite its many benefits, some projects may require alternatives. Assessing the specific needs of a project can lead to more informed decisions. A thoughtful approach is essential for optimal results.

Economic Advantages of Using Welded Wire Mesh

Welded wire mesh is becoming a popular choice among builders and DIY enthusiasts. Its economic advantages are hard to ignore. This material is often less expensive than alternatives. You can reduce costs without sacrificing quality. It is durable and long-lasting, making it a smart investment.

Using welded wire mesh can streamline your project. It’s easy to handle and quick to install. You save time and labor costs. Projects wrap up faster, which can be a significant advantage. Yet, one must consider the source of recycled materials. They can sometimes lack consistency in quality.

Many projects benefit from the versatility of welded wire mesh. It adapts well to different uses, from fencing to forming concrete supports. However, be cautious about choosing the right size and gauge for your specific needs. A mismatch can lead to weaker structures. It's crucial to reflect on the potential trade-offs before committing to this material. Balancing cost and durability requires careful thought.

Durability and Longevity of Welded Wire Mesh Products

Welded wire mesh stands out for its durability and longevity. This makes it an excellent choice for various projects. According to industry research, products made of welded wire mesh have a lifespan of over 30 years when properly maintained. Such longevity reduces the need for costly replacements.

The material’s resistance to corrosion and rust also contributes to its impressive durability. Studies show that welded wire mesh can withstand harsh weather conditions without significant degradation. This resilience makes it suitable for both indoor and outdoor applications. Projects that prioritize longevity often benefit from this robust material.

Tips: Always choose the right gauge for your specific needs. Thicker wires provide more strength. Regular inspections can help catch wear early, extending lifespan. Remember, an informed choice leads to better results.

Installation and Maintenance Considerations for Welded Wire Mesh

Welded wire mesh offers a robust solution for various construction projects. However, the installation process requires careful attention. Properly aligning the mesh is crucial to ensure its strength and stability. Misalignment can lead to structural weaknesses. Statistics indicate that improper installation accounts for nearly 25% of mesh-related failures.

Maintenance is another key consideration. Even though welded wire mesh is durable, it can suffer from rust if not properly coated. Regular inspections are essential. In a recent industry survey, 40% of respondents noted that neglecting maintenance led to significant damage over time. Cleaning and re-coating can extend its lifespan significantly.

When using welded wire mesh, consider environmental factors. Exposure to moisture can accelerate corrosion. Using protective treatments is wise. However, these treatments can wear off, so remember to check regularly. Ignoring these aspects can result in costly repairs or replacements. Stay proactive about installation and upkeep to avoid future issues.