Top 5 Tips for Choosing a Laboratory Sample Pulverizer?

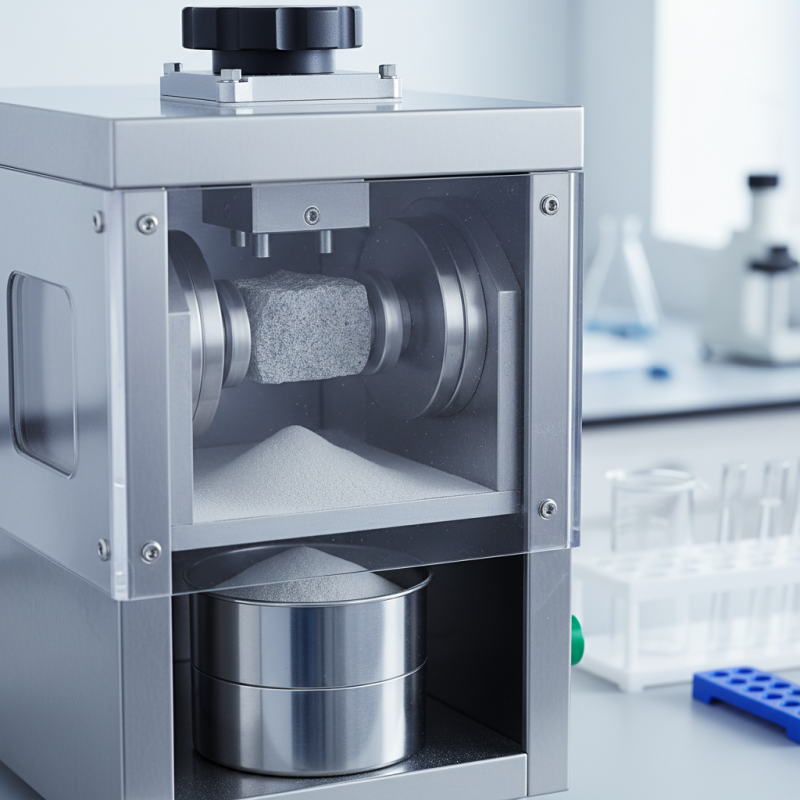

Choosing the right laboratory sample pulverizer is crucial for accurate sample preparation. The right equipment can significantly influence your research outcomes. An effective pulverizer ensures uniform particle size and reduces contamination risk.

When selecting a laboratory sample pulverizer, consider various factors. Your specific application matters. Some pulverizers are better suited for hard materials, while others excel with soft samples. Evaluate the grinding mechanism and capacity. An appropriate choice can enhance efficiency in your lab.

Budget constraints may lead to tough decisions. Investing in high-quality equipment is essential, but it can be challenging. A poorly chosen pulverizer can compromise the quality of your results. Reflect on past experiences and seek user reviews. These steps can guide you to a more informed purchase decision.

Understanding the Purpose and Applications of Sample Pulverizers

Sample pulverizers play a crucial role in laboratory settings. They are designed to reduce materials into fine powders. This process is essential in various fields, including mining, pharmaceuticals, and food science. Understanding their purpose can help in selecting the right pulverizer.

When considering applications, think about the material type. Different materials require specific pulverizing methods. A glass sample needs a different approach compared to soil or herbs. This diversity in applications highlights the importance of choosing a suitable device. Think about the desired particle size and how the final product will be used. Not all pulverizers are versatile enough for every need.

Also, it's essential to consider how often a pulverizer will be used. A heavily used machine might need robust features. However, this could lead to higher maintenance costs. Always evaluate the trade-offs. Reflecting on these aspects helps ensure effective use of laboratory resources.

Key Features to Consider When Selecting a Laboratory Pulverizer

When selecting a laboratory sample pulverizer, it's crucial to consider several key features. The particle size reduction capability is essential. Many laboratories need specific particle sizes for accurate analysis. According to industry reports, achieving particle sizes below 10 microns can be critical for precise results. Thus, you must choose a pulverizer that can consistently meet this requirement.

Durability and maintenance are another vital aspect. Laboratories often operate under rigorous conditions. A durable machine can withstand wear and perform reliably over time. Regular maintenance can sometimes be overlooked, yet it is fundamental for optimal operation. A poorly maintained pulverizer can lead to inconsistent results that may undermine research integrity.

Ease of use and safety features should not be underestimated. Complex machinery can lead to operator errors. Machines with clear interfaces and straightforward operating procedures help mitigate risks. Safety features like automatic shut-off mechanisms are essential as well. They ensure the safety of the operator, especially in high-volume environments. For a successful laboratory operation, these features are not mere options; they are necessities.

Evaluating the Material Compatibility of Pulverizers

When selecting a laboratory sample pulverizer, evaluating material compatibility is crucial. Different materials require specific pulverization techniques. For instance, a study indicates that ceramic materials can be subject to wear and tear from metal components in pulverizers. This can lead to contamination, impacting analytical results.

Understanding the hardness of materials is part of the compatibility evaluation. Harder materials may demand special grinding attachments. A report from the International Journal of Mineral Processing highlights that using incompatible grinding surfaces results in a 15% increase in particle size variation. This is significant in high-precision applications.

Additionally, the type of sample affects pulverization efficiency. For example, organic materials may produce moisture that affects the grinding process. If not addressed, this can lead to clumping and uneven particle distributions. Choosing the right materials for your pulverizer is not just a matter of preference; it's essential for obtaining accurate lab results.

Assessing Size and Capacity Requirements for Your Laboratory Needs

When choosing a laboratory sample pulverizer, size and capacity are crucial. Determine the type of samples you'll be working with. Different materials may require different approaches. A larger pulverizer may handle bulk samples well but could waste energy on smaller tasks.

Next, think about your workload. How many samples do you process daily? High throughput requires a capable machine. If your needs fluctuate, consider a flexible option. Make sure the size matches your space. A big pulverizer in a small lab can be an obstacle, leading to inefficiencies.

Assessing these factors can be tricky. You may need multiple prototypes to gauge effectiveness. Some samples might crush perfectly while others do not. This inconsistency demands attention. A space-saving model might compromise capacity. Balancing these elements is essential for optimal performance.

Maintaining and Operating Best Practices for Sample Pulverizers

When it comes to operating a sample pulverizer, best practices are essential. This equipment plays a critical role in material analysis and preparation. Regular maintenance is key to its longevity. Dust and debris can accumulate quickly, affecting performance. It’s recommended to clean the machine after every use to prevent contamination in future samples.

One tip is to ensure that all parts are properly calibrated. Misalignments can lead to inefficient processing, affecting the quality of your results. According to industry reports, a well-calibrated pulverizer ensures a 20% increase in sample consistency. The wear of grinding elements also requires monitoring. Scheduled replacements can prevent unexpected breakdowns.

Another important factor is operator training. Lack of knowledge can lead to accidental misuse. A study highlighted that well-trained operators significantly reduce equipment damage incidents by up to 30%. Providing regular training sessions can improve team competency. Involving employees in discussions about operational challenges can lead to insights. Maintenance logs should be kept detailed. These logs can reveal recurring issues, highlighting areas needing attention.